The evolution of sports car body repair has revolutionized the automotive industry, driven by demand for high-performance machines. Advanced technologies like CAD and 3D printing ensure precise measurements and exacting repairs, preserving unique vehicle contours. This innovation has reshaped manufacturing processes, setting new benchmarks for quality and precision, while enabling restoration of classic models and increasing customization options. Modern repair methods leverage computer-aided design software and laser welding for near-perfect results, enhancing service quality and reducing costs. Advances in materials science have also contributed to lighter, more durable body panels, improving fuel efficiency and performance across vehicle types.

Sports car body repair has evolved from art to science, revolutionizing the auto industry. Once considered a niche craft, it’s now a driving force behind advanced manufacturing techniques and precision engineering. This transformation isn’t just about aesthetics; it impacts every aspect of automotive production, from materials science to digital design. Let’s explore how sports car body repair has changed the game for auto manufacturers, pushing boundaries and setting new standards in vehicle construction and repair.

- Evolution of Sports Car Craftsmanship

- The Impact on Auto Manufacturing

- Revolutionizing Repair Techniques and Technologies

Evolution of Sports Car Craftsmanship

The evolution of sports car craftsmanship is intrinsically linked to advancements in sports car body repair techniques. Historically, sports cars were renowned for their sleek, aerodynamic designs but often lacked the intricate build quality of mainstream vehicles. However, as the demand for high-performance machines grew, so did the need for sophisticated repair methods. Auto enthusiasts and skilled technicians began pushing boundaries, refining not just performance but also the art of restoration and repair.

Modern sports car body repair has become a testament to automotive craftsmanship, with each vehicle treated as a unique work of art. Advanced technologies like computer-aided design (CAD) and 3D printing have enabled precise measurements and exacting repairs, ensuring that every curve and contour remains true to the original vision. This level of detail is not only visible but also feels tangible when experiencing these vehicles up close, showcasing the dedication and skill of automotive body shops across the industry.

The Impact on Auto Manufacturing

The evolution of sports car body repair has left an indelible mark on the auto industry, revolutionizing manufacturing processes and setting new standards for quality and precision. As the demand for sleek, high-performance vehicles grew, so did the need for advanced repair techniques. Sports car body repair shops became pioneering hubs where skilled artisans and engineers collaborated to develop innovative solutions for intricate vehicle structures.

This shift led to a significant transformation in auto manufacturing. Vehicle body shops embraced frame straightening technologies, ensuring that even the most damaged cars could be restored to their original structural integrity. The art of automotive restoration gained prominence, allowing manufacturers to revive classic models and cater to collectors worldwide. This new focus on meticulous repair methods sparked a trend towards increased customization, as car enthusiasts sought unique, personalized vehicles.

Revolutionizing Repair Techniques and Technologies

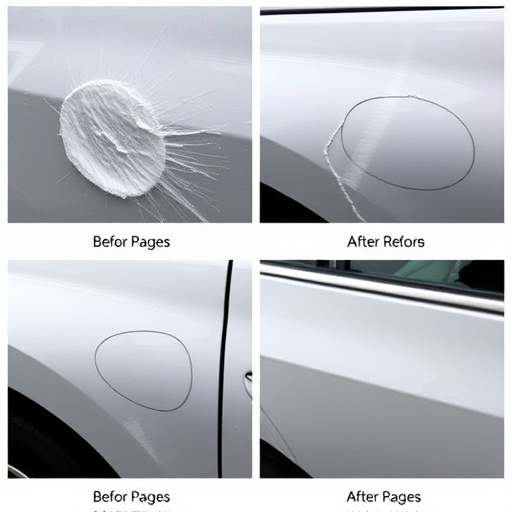

The evolution of sports car body repair has been a game-changer for the automotive industry, revolutionizing repair techniques and technologies. In the past, vehicle repair was often a time-consuming and laborious process, with little room for precision and customization. However, advancements in sports car body repair have transformed these limitations into opportunities.

Modern repair methods involve sophisticated equipment and techniques, such as computer-aided design (CAD) software and laser welding, which enable technicians to achieve near-perfect results. This has not only improved the quality of automotive repair services but also reduced the overall cost and downtime for car owners. Additionally, innovations in materials science have led to lighter and more durable body panels, further enhancing fuel efficiency and performance across various vehicle types, including those that were once exclusively sports cars.

Sports car body repair has evolved into a game-changer for the auto industry, revolutionizing manufacturing standards and pushing technological boundaries. As we’ve seen, the meticulous craftsmanship once reserved for exclusive sports cars has trickled down, enhancing overall vehicle quality and repair efficiency. With innovative techniques like laser straightening and advanced composite materials, the future of automotive repairs looks promising, ensuring faster, more precise, and environmentally friendly restoration processes. This transformation underscores the continuous drive for excellence in the industry, driven by the pioneering spirit of sports car body repair.